Scope & Objectives

The ROCCS project is built on the experience and recommendations of past projects in Europe and globally, to develop an effective engineering practice for the CO2 storage in coal. This will be achieved by testing the potential of horizontal wells to deliver sustained rates of CO2 injection by overcoming CO2-induced coal swelling. Compared to vertical wells, horizontal wells enlarge the coal-CO2 contact area with the potential to improve flow by taking advantage of preferential flow pathways formed by local heterogeneity. Measurement of the relationship between CO2 injectivity and coal-CO2 contact area will be combined with laboratory testing, numerical modelling, site monitoring, risk assessment and techno-economic assessment to determine the potential of this engineering practice.

The overall objective will be achieved through the following activities:

• Development of an in-situ test facility at Experimental Mine Barbara in Mikołów, Poland.• Baseline monitoring and characterisation of the selected site.• Design of the gas injection and recovery systems and active monitoring system.• Design and installation of a state-of-the-art horizontal well system, including injection and horizontal pressure release wells, with a Packer-and-Port design for zonal isolation to incrementally control the coal-CO2 contact area.• Completion of the in-situ test with CO2 injection over a period of 3 to 6 months.

• Evaluation of the effectiveness of using the horizontal well in elevating the rate of CO2 injection and storage.

• Identification, assessment, and management of risks for long-term safety and containment of stored CO2.

• Design and evaluation of a commercial CO2-storage unit selected by the industrial partner PGG, for elaboration and upscaling of the findings from the in-situ test.

• Numerical modelling for post-analysis of the in-situ test, and for design and evaluation of the commercial unit, including near-field and regional hydromechanical analyses.

• Techno-economic assessment and optimisation of the use of required surface and subsurface infrastructure at minimum operational costs.

• Preparation of best practice guidelines to support the commercial development of CO2-storage unit using the state-of-the-art horizontal wells.

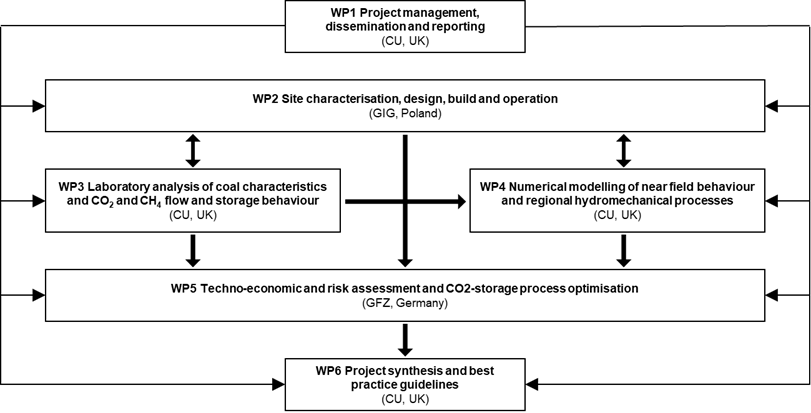

Work Packages

WP1:

Project management, dissemination and reporting

WP2:

Site characterisation, design, build and operation

WP3:

Laboratory analysis of coal characteristics and CO2 and CH4 flow and storage behaviour

WP4:

Numerical modelling of near field behaviour and regional hydromechanical processes

WP5:

Techno-economic and risk assessment and CO2 storage process optimisation

WP6:

Project synthesis and best practice guidelines

Project Tasks

WP1: Project management, dissemination and reporting

- Task 1.1 Project coordination and scientific management

- Task 1.2 Project management, EU communications and IPR

- Task 1.3 Internal communication

- Task 1.4 Dissemination of results

WP2: Site characterisation, design, build and operation

- Task 2.1 Experimental site characterisation

- Task 2.2 Design of experimental setup and adaptation of existing installation

- Task 2.3 Plan, design, and operation of the monitoring system

- Task 2.4 In-situ tests of CO2 injection

- Task 2.5 Database and 3D static geological model development

- Task 2.6 Site selection and characterisation for future commercial-scale development

- Task 2.7 Design of a commercial-scale installation for CO2 storage

WP3: Laboratory analysis of coal characteristics and CO2 and CH4 flow and storage behaviour

- Task 3.1 Preparation and characterisation of coal samples from Experimental Mine Barbara and the selected coal deposit

- Task 3.2 Gas sorption capacity and sorption kinetics measurements on powdered and intact coal samples

- Task 3.3 Coal permeability measurements using large intact cores with flow of selected gas species

- Task 3.4 Core flooding experiments on large intact cores for CO2 injection and methane displacement behaviour

- Task 3.5 Large-scale ex-situ laboratory test of CO2 injection process using pressure reactor

WP4: Numerical modelling of near field behaviour and regional hydromechanical processes

- Task 4.1 Pre-operational numerical simulations to assist design of in-situ test

- Task 4.2 Prediction of potential CO2 storage using horizontal wells at a commercial-scale site in Poland

- Task 4.3 Far-field simulation of hydromechanical processes

- Task 4.4 Post-operational analysis of CO2 flow behaviour observed in the in-situ test

WP5: Techno-economic and risk assessment and CO2 storage process optimisation

- Task 5.1 Techno-economic model adaptation

- Task 5.2 Techno-economical risk assessment and process optimisation

- Task 5.3 Prediction of cost bandwidth based on the identified environmental risks

WP6: Project synthesis and best practice guidelines

- Task 6.1 Best practice guidelines for CO2 storage based on the use of horizontal wells

- Task 6.2 Review of the existing permitting and regulatory framework for CO2 storage in Europe and implications of ROCCS outcomes for regulators

ROCCS is funded by the European Union Research Fund for Coal and Steel (EU- RFCS) under the grant agreement No 899336

© 2020 ROCCS. All Rights Reserved.